BAM Example from West Africa

Cashew Processing Plant in Catel, Guinea-Bissau

This BAM example is in a rural West African village. An increasing array of example projects is not accessible via the internet. The article was complete with photos and written by Beryl Forrester, of Eastern Minnonite Missions. The accompanying photo is also by Beryl Forreste. Here are some excerpts from his piece.

"This isn’t the first such industry for Catel, but it is the first one to actually process locally grown agricultural products for the global market, Forrester said. In the past, the abundant crop of local cashews often rotted on the ground, going to waste without proper processing and marketing procedures.

Forrester said the new plant “is still back there a century or two,” but it’s appropriate technology for Catel.

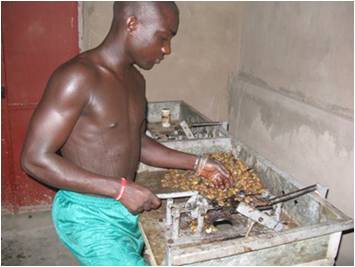

First the nuts are boiled in the husks over a fire fueled with husks from the previous batch. The husks, which contain a highly flammable petroleum product, burn well.

After the nuts have been cooked, a hand-operated mechanical knife splits open the softened husks, and workers pop out the cashew kernels with nails. Each cashew is handled individually several times, making for rather tedious labor

“It might be boring,” Forrester said, “But it sure beats sitting day after day on the veranda with nothing to do but visit and drink tea.” He enjoys hearing the hum of workers’ happy conversation blended with the squeak and clunk of the nut crackers.

Most of the 10 employees are young adult students. Their earnings, which aren’t yet up to what Forrester is aiming for, are paying for school fees.

In the new year, they plan to add a roasting facility and eventually a packaging unit. In the long term, they hope to export internationally and open similar processing units in other villages. Forrester believes the cashew processing business has great potential in West Africa.

As they build up a larger stock of nuts and include more processing steps, Forrester believes they could easily triple in size in the coming year. This past fall they produced 150 pounds of shelled nuts a week.

Mamadou Mane operates a cashew nut cracking machine at the new cashew processing plant in Guinea-Bissau. Each nut must be held in place individually as the worker – using both hand and foot – manipulates the blade that cracks open the nut. Photo credit: Beryl Forrester

Forrester is pleased with initial indications of profitability. “We want both just wages for the workers and a modest profit that, in the years to come, will sustain the business and subsidize the work of the church and our nongovernmental organization – Mennonite Educational & Horticultural Development Associates,” he said. “I firmly believe it can be done.”

Forrester sees the new plant as a good example of “business as mission.” It utilizes local resources, both human and agricultural, to create opportunities for people in poverty to take responsibility for their own lives.

It’s also an acknowledgement that God has placed wealth on earth that can sustain human life, dignity, and a better tomorrow. It puts an end to dependency on overseas dollars and a “poor me” mentality.

In addition to Forrester, the EMM team in Guinea-Bissau includes Andrew Stutzman and a six-member Youth Evangelism Service (YES) team that began eight months of service in December.

Seven small church fellowships have been started in Catel and the surrounding villages."

Many thanks to Beryl for providing this example on the internet. Some interesting a key points that are congruent with our discussion include:

- This BAM takes advantage of local product -- cashews

- In start-up, the processing is very labor intensive, far from modern processing, but that is okay for this place at this time

- The vision includes growth and profitability

- Earnings for the workers will improve quality of life -- a means of education

- The BAM accompanies church fellowships in the villages

Thanks for your interest,

Larry

|